Install Chain Link Fence Slope

- Install Chain Link Fence Slope Table

- Cutting Chain Link Fence

- Install Chain Link Fence Slope Calculator

Installing a chain link gate on your fence is the perfect way to make your property more accessible—and it’s something you can do at home on your own. This how-to guide from America’s Fence Store will teach you the basics of chain link gate installation.Objective: By mastering this lesson, you will be able to successfully measure for and install chain link gates.Equipment: Socket set, hammer, come-a-longs, level and pliers.Key Questions:. How do I measure for gates?.

How do I install a cantilever gate?. How do I install a rolling gate?. What are the most common safety obstacles to be aware of when installing gates?How do I measure for gates?With all gates, make sure that you get more than one measurement. Following a level plane, you will want to measure both at the top and bottom of the gate. Do not allow your tape to slope or angle from level while measuring. Keep your dimensions accurate to + 1/8”.

You will often times find these dimensions are different. Generally, the smaller dimension is used in building the gate. Communicate this information clearly on your as-built shortly after setting the posts.Rolling gates: Measure from inside to inside of gate posts and from inside to inside of the adjoining line posts that will support the gate when in the full open position. The inside to inside of line post should not exceed 8’Cantilever gates: Measure from inside to inside of the latch posts to the first gate or roller post.

This would be the gate post closest to the opening. Then, measure from outside to outside of gate or roller gate posts. See illustration.How do I install a cantilever gate?A cantilever gate should be installed on a level plane so that the gate can roll in both directions without having additional gravitational pull as a result of the weight of the gate. Slight adjustments can be made to allow for some minor slope, however, too much slope and the gate could prove to be dangerous while rolling downhill. To install a cantilever gate:. Install the two bottom cantilever rollers so that the rollers are toward the inside of the fence while fabric is on the outside. The rollers should be approximately 1” off the ground.

Place a piece of rail across the two rollers. Place a level on the rail and adjust the rollers up or down so that the rail is level. Also, make sure that the rollers are adjusted so that the gate will not slide into the grade as a result of a slope. Tighten the rollers. Install the two top cantilever rollers so the rollers will capture the gate once in place. Hand tighten the rollers.

Install the gate onto the two bottom rollers. Stand the gate up.

When in the upright position, slide the two rollers over and onto the gate. With the gate touching both bottom rollers (balanced in-between the rollers), tighten the two top rollers, leaving a ½” clearance between the rollers and top of gate frame (track or 2.5” pipe). Tighten the rollers. Roll the gate forward and backwards through the opening. If the gate binds, you may have to raise one of the top rollers.

Install Chain Link Fence Slope Table

Adjust the rollers as needed so that you keep the gate as close to the ground as possible, but do not place the rollers below grade or buried. In the winter, the areas around the rollers will fill with snow and freeze. Do not dig a trench for the gate to fully open.

Again, in the winter the snow will freeze the gate in place. Fully tighten all rollers upon completing final adjustments.

Install the latch assembly. If installing a gate operator, use the large “V” receiver that allows the gate to be channeled into the receiver. If manually operating the gate, use a cantilever locking device so that a padlock may be applied.How do I install a rolling gate?A rolling gate is great for applications with not enough room to store cantilever gate and openings with a fair amount of slope. However, you must have a smooth surface to roll the gates from ground wheels along the opening.

To install a rolling gate:. Make sure that you set your posts that will support your track on 8’ centers and used at least 2 ½” Sch 40 posts.

A rolling gate uses two wheels installed on the back vertical support of the gate. These wheels run along track that is installed along the inside of the fence. Install your universal track brackets one foot from the bottom of the fence and one foot down from the top of the fence.

The brackets are installed so that the U-bolt is below the track sleeve. You will need to install enough brackets to support as many 8’ lengths of track as required to bring your gate to the full opening, i.e.

20 opening will require three lengths of track (24’). Measure from bracket to bracket. Using 1 5/8” Sch 40 pipe, cut your track and install between the brackets. Be sure that your track is tight between the brackets so that we do not create a seam for the wheels to get caught-up. Once complete you should have a top and bottom track that is consistently the same distance apart from one end to the other.

This is important to prevent the track from binding on the rear track wheels. Install your rear track wheels on the rear vertical support of the gate from. The wheels will be approximately one foot from the top and bottom of the gate. The wheels will be installed on the outside face of the gate so as to ride on top of the track. Hand tighten. Install the double wheel carrier as far forward as you can on the bottom horizontal member of the gate. Placing the gate in the opening with both rear track wheels on top of the track, adjust the rear track wheels so that both wheels bear down on the track.

Make sure the lower guide on the wheels captures the track so that you cannot lift the gate off the track but the guide does not bind while traveling the track. Tighten the wheels. Roll the gate through the opening. Adjust the rear track wheels as necessary.

The double wheel assembly has an axle trim bolt that allows you to control the direction of the gate as it rolls through the opening. Adjust as necessary. Using two end bands that fit around the latch post, install the offset lock n’ latch so that when the gate comes fully closed the tab on the latch is engaged, capturing the gate frame and allowing you to padlock the latch.

You may have to adjust the double wheel assembly back on the frame so that the gate will engage the latch. Firmly secure all nut & bolt connections to avoid future movement.What are the most common safety obstacles to be aware of when installing gates?Lifting.

Gates are always heavy, large and awkward. Be sure to use good lifting techniques, plenty of manpower or equipment. Being awkward, it is easy to strain or twist your back.Fall Hazard. Gates have proven to be a real fall hazard. Often times, we lean a gate up against an opening while installing the hinges, a light breeze or bump and the gate will come crashing down on the installer below. Always use a bungee cord, chain, rope to tie the gate up against the fence.

When installing a cantilever gate, use a bungee cord. This will allow you to move the gate in and away from the rollers without having to remove the cord.Cuts. Gates have moving parts. It is easy to catch your finger in a cantilever roller while adjusting the roller.Motorized Hazards.

Motorized gates have enormous potential to create harm. These gates have caught the public eye with a sharp rise in injuries over the years. Consequently, there is a UL 325 Code that governs motorized gate installation. While installing these gates, it is easy to get pinched in a roller, between a picket and post or in the opening.

More on this later.© 2018 The American Fence Company. All rights reserved. Permission granted to reproduce for personal and educational use only. Commercial use, copying or distribution is prohibited without express written permission from The American Fence Company.© 2019 The American Fence Company.

All rights reserved. Permission granted to reproduce for personal and educational use only. Commercial use, copying or distribution is prohibited without express written permission from The American Fence Company.

How to Build a Chain Link Fence Save Money and Learn how to Build a Chain Link FenceMany of our customers these days are “do it your-selfers” who are interested in purchasing fence materials from us and then saving money by building it themselves. This increasingly popular approach has lead us to put together a pamphlet that many customers find helpful when tackling an installation project themselves. Building a fence can be difficult and time consuming but we aim to help lighten the load and are happy to answer any questions you may have. Hire a ProfessionalIf installing a fence isn’t your thing, we provide professional installation at an affordable rate.

Please visit our or for more information. Installation InstructionsBefore you start, make sure your boundaries andproperty lines are legally established.Please read these instructions carefully.Lay out fence lines to determine where to locate your terminal posts (end, corner, and gate posts).

Drive stakes as illustrated at exact boundary line.If you wish to install a 36 inch wide gate, leave exactly 36 inches between gate posts as measured from inside face of gate post. Setting Posts In Concrete:Pour the concrete – one part cement, two parts sand, four parts gravel OR prepare dry cement mix in bags (follow directions on bag for mixing). DO NOT MIX TOO WET. Pour a foot depth at a time and tamp down firmly to remove air holes. Use a carpenter’s level to set posts plumb and in correct position to boundary lines.No two pieces of ground are alike or completely level and you should take this into account as you determine your fence installation. To make the top of your fence straight, you must compensate for ground level variations by adjusting the amount of post above ground to a level line of sight. In some cases it may be necessary to trench the ground at a particular high ground level, or if ground is low, it may require filling with dirt.After concrete has set long enough to be hard (approximately three days), begin to assemble the fittings.

Slide tension bands onto end and corner posts. Be sure long, flat side of tension band is to the outside or wire side of posts, and that there is approximately one band for each foot of the post. Place eyetops on each of the line posts with offset toward wire side of posts. Place brace bands on terminal posts. Attach rail end fittings to brace bands, bolting them together loosely as illustrated.

Thread top rail through eyetop and into one rail end. In the event you must join two lengths of top rail, make sure top rail joints are sleeved near a line post.

Please note illustrations (a top rail sleeve is used to join two lengths of top rail together, however if a swedged end top rail is used, no sleeve is necessary). Put on a sleeve and continue with top rail to next terminal post. Cut last length of top rail to fit all the way into sleeve and tightly into the remaining rail end.

Once top rail is in position, tighten all brace bands and rail end bolts securely. Put cap fittings on all terminal posts.The wire fence fabric is next. Unroll it along wire side of the fence line with desired edge in position. Insert a tension bar through the last vertical row of chain link wire, nearest a gate, end, or corner post. Stand end of chain link up and put tension bar in tension bands. Install band bolts with thread towards inside of fenced area. Tighten bolts as necessary to maintain fabric at proper height.

Unroll chain link against fence frame. Loosely secure fabric to top rail to hold vertically as necessary. Chain link fabric must be stretched to take out slack.

Attach fence stretcher. It is connected between a stretcher bar (attached to the chain link vertically) and the corner of end post. Stretch fabric taut; remove excess fabric at end post (see illustration for splicing). Insert tension bar, attach to tension bands and bolts as before.Tie fabric to fence frame. Tie fabric to top rail raising fabric to desired level asyou do so. Space tie wires approximately 24” apart (three ties on each line post, minimum). Tighten nuts on all tension and brace band bolts (please note illustration).

You may install chain link fabric two ways. The fabric may have smooth loops on one end and barbed ends on the other.

For most residential installations, it is recommended that fabric is installed with smooth edge up. In the event added security is necessary, you may install fabric with barbs up.To shorten or take two sections apart, untwist wire at barbed end of fabric at the desired place. Loosen wire at top of fabric and begin to corkscrew the loosened picket out, separating the two sections.

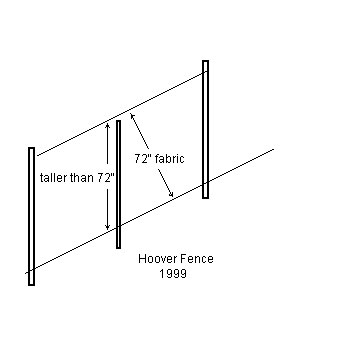

To splice two sections, you must be sure you start with a whole diamond on one side and a half diamond on the other. Start at the top of the fabric and corkscrew wire picket down through the ends of the sections. Twist the wires together at barbed ends if applicable and attach top of picket to the looped end.The posts are installed vertically on the slope while the chain link is square. The tension bars are put through the chain link parallel to the post and the excess trimmed off. Also, the length of the post must be proportionately longer, depending on slope angles (see illustration).There are many types of latches including the standard fork latch (see illustration) and the butterfly latch, also illustrated. The butterfly latch is a self-latching fitting and is used primarily for self-closing gates. Walk-In GateSet gate posts to exact opening dimension.

Cutting Chain Link Fence

For example, for a three foot opening set gate posts exactly three feet apart measured from the inside face of each post. The gate hinges should be mounted with top hinge pin down and bottom hinge pin up. Hang gate to give 2” clearance at the ground. Mount the bottom gate hinge on bottom pin first so top of gate is parallel to top of fence fabric. Adjust top gate hinges accordingly. Mount gate latch to gate frame.Mount gate latch to one of the gate frames. A hole or notch in the ground should be made, as illustrated, to secure the double gate latch.To install a double opening gate, for example across a driveway, determine exact opening (dimensions measured from inside face to inside face of gate posts).

Install Chain Link Fence Slope Calculator

Allow 2” at the bottom of the gates for ground clearance. Mount gate hinge and hinge pins the same as the single gate, being sure to line top of gates parallel with fence fabric.

Materials Needed For Residential Chain Link Fence Fence Layout.